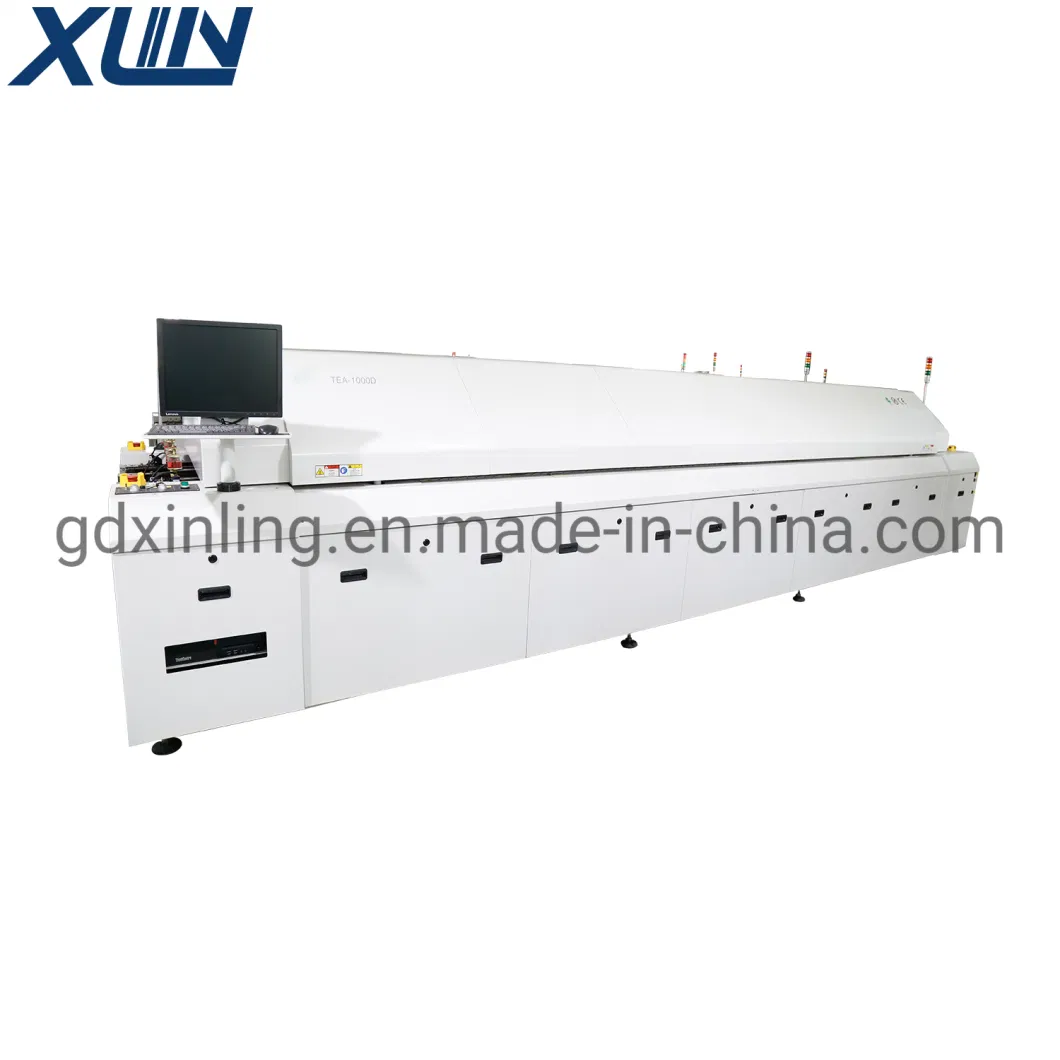

Used Reflow Soldering Machine with High Quality Jt Tea

Basic Info.

| Model NO. | X8-TEA-1000D |

| Automatic Grade | Automatic |

| Type | High-speed Chip Mounter |

| Quality | 100% Tested |

| Inventory | Availability |

| Adaptation | SMT Placemnt Assembly |

| MOQ | 1 Set |

| Delivery | 7-10 Days |

| Transport Package | Plastic Bag&Carton Box |

| Specification | 6000*1660*1530mm |

| Trademark | JT |

| Origin | China |

| HS Code | 8514109000 |

| Production Capacity | 500PCS/Year |

Product Description

Product DescriptionJT Reflow Oven X8-Tea-1000D

DetailsLow nitrogen consumption, 300-800ppmNitrogen closed-loop control system is optionalThe fully enclosed design is adopted in the furnace to effectively reduce the loss of oxygen and nitrogen gas, and the minimum oxygen content can be reduced to 150ppm.The improvement of 15% heat transfer efficiency can calmly meet the lead-free process requirements of large welding qualityThe track adopts special hardening treatment which is durable

| Model | X8-TEA-1000D |

| Machine parameters | |

| Dimension(L*W*H) | 6000*1660*1530mm |

| Weight | Approx 2955kgs |

| Number of heating zone | top 10/bottom 10 |

| Length of heating zone | 3895mm |

| Number of cooling zone | top 3/bottom 3 |

| Rectifying plate structure | Small circulation |

| Exhaust volume requiement | 10m³/min*2(Exhausts) |

| Color | Computer grey |

| Control system | |

| Power supply requiement | 3 phase ,380v 50/60HZ(Option:3 phase ,220v 50/60HZ |

| Total power | 83 KW |

| Startup power | 38 KW |

| Normal power consumption | 11 KW |

| Warming time | Approx:20min |

| Temperature control range | Room Temperature -300ºC |

| Temperature control method | PID close loop control + SSR driving |

| Temperature control precision | ±1ºC |

| Temperature deviation on PCB | ±1.5ºC(by RM board test standard) |

| Data storage | Process data and status storage |

| Abnormal alarm | Abnormal temperature(extra-high/extra low temperature after constant temperature) |

| Board dropped alarm | Singal light(yellow-warning;green normal;red -Abnormal |

| Conveyor system | |

| Rails structure | Overall sectional type |

| Chain structure | Double buckle for preventing board jammed |

| Max width of PCB | 400mm(option:460mm) dual-rail 300mm*2 |

| Range of rail width | 50-400mm(option:50-460mm) dual-rail 300mm*2 |

| Component height | Top 30/Bottom 30mm |

| Conveyor direction | L→R(option:R→L) |

| Conveyor rail fixed type | Front rail fixed(option: Rear rail fixed) |

| PCB conveyor direction | Air-reflow=chain+mesh(N2-reflow=chain option:mesh) |

| Conveyor height | 900±20mm |

| Conveyor speed | 300-2000mm/min |

| Auto-lubrication | Multi-lubricating mode can be chosen |

| Cooling system | |

| Cooling method | Firced air Water chiller |

Company Information:

| COMPANY PROFILE |

Guangdong Xinling Industrial Co., Ltd. is a high-end brand manufacturer of fully automatic AOI visual inspection equipment, which integrates research and development, manufacturing, sales and service.

and we are the leading SMT machines and solution with 10 years' experience in China. and we are aslo the only Chinese SMT supplier for ASM factory in China.

Our advantage

1st,We have strict inspection standards for the quality of our products, which has formed a high-standard process system;2nd,We have a strong price advantage, absolute price advantage is the best choice for customers;3rd, our business philosophy: "Customer first, Quality first " Principle;4th, We are a big international brand level agents and over the years we accumulated a high quality customer resources;5th, We have a global sourcing, huge demand we can reduce the purchase cost. More new accessories supply to ensure our sustainable supply and price advantage.

Successful Experience:Xlin's customer in 30 countries around the worldWe have been helping customers to build a lot of new factories around the world.We hope Became the most reliable Chinese partner for you.

COOPERATION BRANDOur Team:

FAQ

1. What products can you provide? Placement Machine Feeder, SMT Placement Machine, SMT AOI, SMT SPI, SMT Stencil Printer, SMT Reflow Oven, SMT X-Ray, SMT Feeder, SMT Nozzle, LED Pick & Place Machine, Wave Soldering Machine, SMT Coating Machine, SMT Cleaning Machine, SMT Label Mounter, PCB Cutting Machine, PCB Laser Printer Machine, PCB Handling Machine, SMT Mounter Sales: Placement Machine, Placement Machine Accessories, SMT Accessories.

2. Can I get a sample? what is your MOQ?Yes, sample is available, our MOQ is 1 piece

3. How long will it take to deliver the goods?About 1 to 7 working days. 4. What kinds of brands of parts can you provide? We have Fuji, Juki, Yamaha, Samsung, Panaconic, Siemens, Universal, Hitachi etc.

5. What is the warranty of feeders?

We provide 6 months` warranty on new feeders and 3 months on Second hand Feeders, actual life depends on working and maintanance. If feeder can not work after newly received , free repalcement would be sent immediately or refund

24 hrs online, quick response, guaranteed warranty for you :)) For more information, please visit our Official website https://gdxinling.en.made-in-china.com